These data indicators give you the answer!

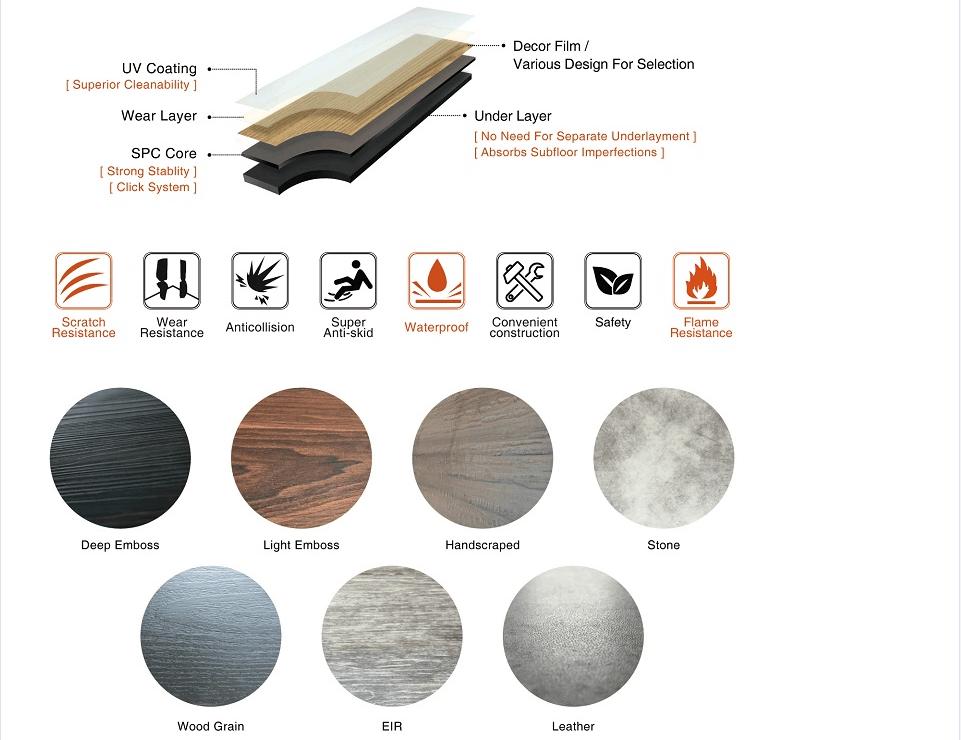

The stone-plastic floor is extruded from the extruder with a T-mould to extrude the PVC substrate. The three-roll or four-roll calender is used to respectively heat the PVC wear layer, PVC color film and PVC substrate. The product is simple in process, close to heat, and does not require glue. Moreover, formaldehyde, heavy metal content and volatile organic content are all “0 content” requirements, which are popular in developed countries in Europe and America and in East Asia.

1, environmentally friendly and recyclable

In the production process, the stone plastic floor is made of new plastic materials and natural stone powder. It does not use any glue, so the floor itself has no irritating odor, and there is no toxic substance. The thickness is generally about 5mm, and some of the bottom is also covered with a cushion, which makes the foot feel more comfortable and can also absorb sound. European and American home improvement is very keen on such flooring.

2, shrinkage rate

The size of the stone-plastic floor is very stable, and its shrinkage is about 0.7‰, that is, 10m shrinks by 7mm, and the temperature changes at 23-60°C, which fully meets the needs of the family.

3, residual depression

The stone plastic floor itself has high hardness and elastic recovery ability, usually expressed by “residual depression”. The professional test is to apply pressure on the floor with 63.5 kg, then remove it to see the degree of depression, stone plastic floor test. The result was 0.6 mm with almost no depression.

4, stain and corrosion resistance

The surface of the stone-plastic floor has a special UV wear-resistant layer, which can effectively prevent the corrosion of acid and alkali. For oil stains and dust in daily use, it can also be cleaned by simply mopping.

The wood grain color in the stone-plastic floor is very much. Due to the continuous advancement of printing technology, the wood grain effect of the stone-plastic floor is extremely realistic, and the difference between the wood-based floor and the solid wood floor is small, and the similarity is very high. In addition, the stone-plastic floor itself also contains a large amount of stone powder, and there is no plastic feeling at all.

A product is difficult to be perfect. Because of the large amount of stone powder added to the stone-plastic floor, the weight is relatively high, especially the lock floor, and the buckle type on the edge is relatively brittle. Be careful when transporting to avoid bumping.

With its excellent stability and durability, the stone-plastic floor not only solves the problem of moisture deformation and mildew of the solid wood floor, but also solves the formaldehyde problem of other decoration materials. It has a wide selection of color patterns, and it will become more and more widely used in indoor home decoration, hotels, hospitals, shopping malls and other public places.

Post time: Nov-15-2021