Wood veneer is widely used in the veneer decoration of furniture and other products. It is a kind of thin veneer or veneer material with the characteristics of precious tree species.

The earliest known use of wood veneer was in Egypt 4,000 years ago, where a tropical desert climate meant that wood was scarce and Ruling class loved it, the craftsmen invented the cutting of wood.

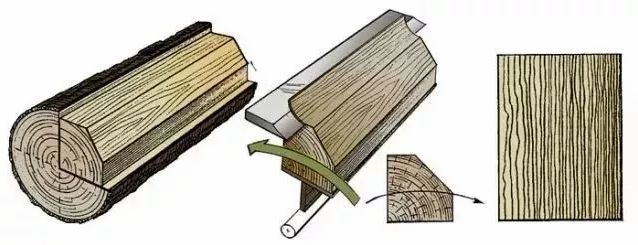

Starting from the production method, it can be divided into string cutting, jing cutting, rotary cutting and cutting material.

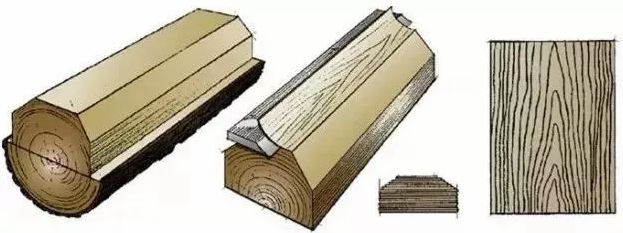

Cut the strings

(Plain Slicing, Flat cut)-also known as Plain Slicing, the string Slicing is a parallel line along the center of the log to cut the wood.

Cut the bark from the opposite log strings, the first layer of rings will form a“Cathedral”-style pattern of wood grain.

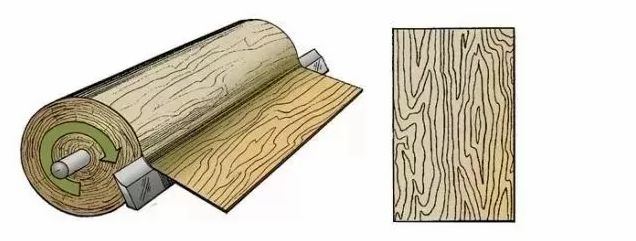

2. Spin-cut

Rotary Cut-place the log in the center of the lathe, insert the slicer into the log at a slight angle, then rotate the log against the Slicer to create a Rotary Cut. The peeled veneer can be widened to provide a whole board (single board) face.

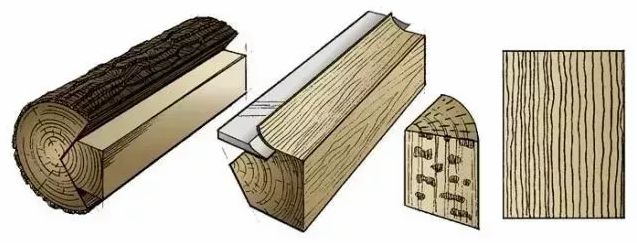

3. Radial cutting

(Quarter Slicing)-radial Slicing is the vertical Slicing of logs to produce bark with a straight grain.

Rift-cut-cut bark is made of various oak. The pith rays of the oak spread out from the center of the log, like the curved spokes of a wheel.

The pith rays are cut at a slight angle to the oak to minimize the appearance of“Scaly” grain and produce a straight-grained bark.

4. Cut the material

(Lengthwise Slicing)-cut the veneer from the bottom of the plank by laying the plank flat with a fixed Slicing knife. The grain patterns of lengthwise-cut bark vary widely.

2 kinds of different products present different styles, performance and characteristics are also different.

The charm of wood veneer lies in its unique grain, rich and beautiful color, as well as natural beauty, making natural wood veneer to go through the rigorous production process to add a different value.

Natural Wood:

It has the natural fragrance and texture of wood, the special and irregular natural texture, the artistic charm of Now You See Me and exquisite workmanship, and the artistic enjoyment of returning to nature. Natural Wood veneer is widely used: thin veneer for veneer, paper and non-woven fabric; thick veneer for wood veneer, furniture making, composite flooring.

Technical Wood veneer:

A new type of wood material with better performance is produced by high-tech processing, recombining and beautifying ordinary fast-growing wood with bionics principle. The books processed from scientific wood are generally called scientific wood veneer.

1 rich color and variety

The utilization ratio of finished products is higher

3 product development potential

4 large size of decorative format

5 convenient processing

3. Dye the bark:

A new kind of decorative material, which is made by using high-tech processing technology to treat and color the defects of natural wood, is commonly known as dyed wood in China.

1 has a natural texture

2 surface zero defect

3 green

3 product technology and classification

There are many criteria for classification:

1 classified by thickness

A thickness greater than 0.6 mm is called thick bark; conversely, it is thin bark.

2 classified by manufacturing method

Can be divided into planing bark; peeled bark; sawn bark; semicircle peeled bark. It is usually made more by planing.

3 classified by morphology

It can be divided into natural bark, dyed bark, technical bark, spliced bark, rolled bark (non-woven fabric bark) .

4 classified by source

Domestic wood veneer; imported wood veneer.

4 construction and installation nodes

As a kind of natural material, wood veneer needs to be attached to other materials in order to play its decorative role. The most common method of use is to press the wood veneer on the wood-based board or finger-joint board, make the wood veneer panel, and then process it into furniture.

If the thickness of the veneer is less than 0.3 mm, you can use latex or adhesive; if the thickness of the veneer is more than 0.4 mm, it is best to use a strong adhesive;

Hand-veneer step:

Soak the bark completely

2 the surface of the object to be pasted clean and smooth, and gelatinize

3 will be affixed to the veneer, the good position of the smooth, and then gently scrape with a scraper flat

Wait for the veneer and glue to dry, then iron the veneer with an iron so that it completely adheres to the bottom surface

5 with a sharp blade, cut the excess wood along the edge

One of the biggest applications of wood veneer is in furniture and crafts. In order to pursue the appearance of beautiful, easy to make, stable performance, cost control and other furniture manufacturing effect, a large number of use of wood, and its effect played to the extreme.

Post time: Sep-09-2022